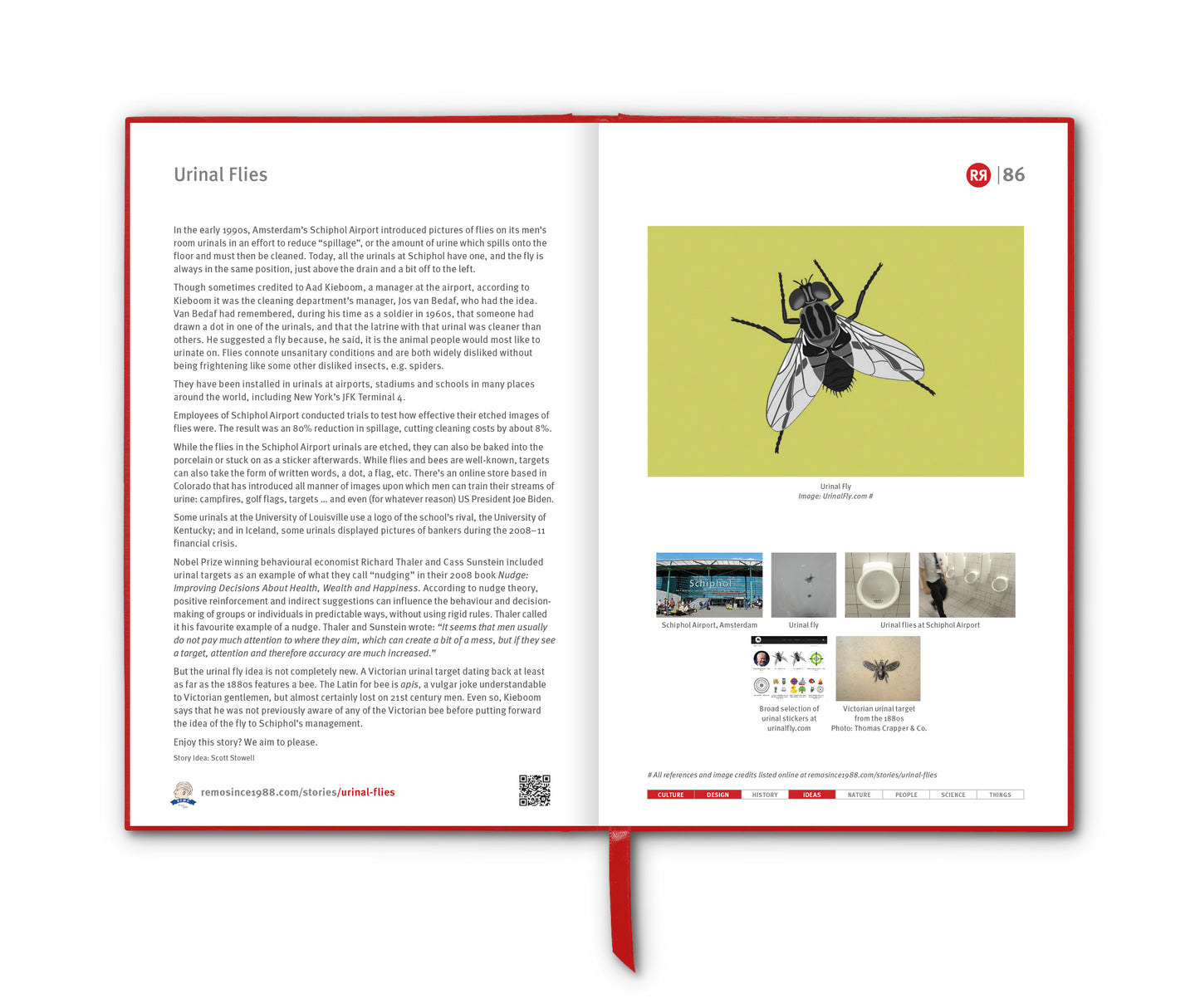

Hand Made in 77 Steps. Built to Last.

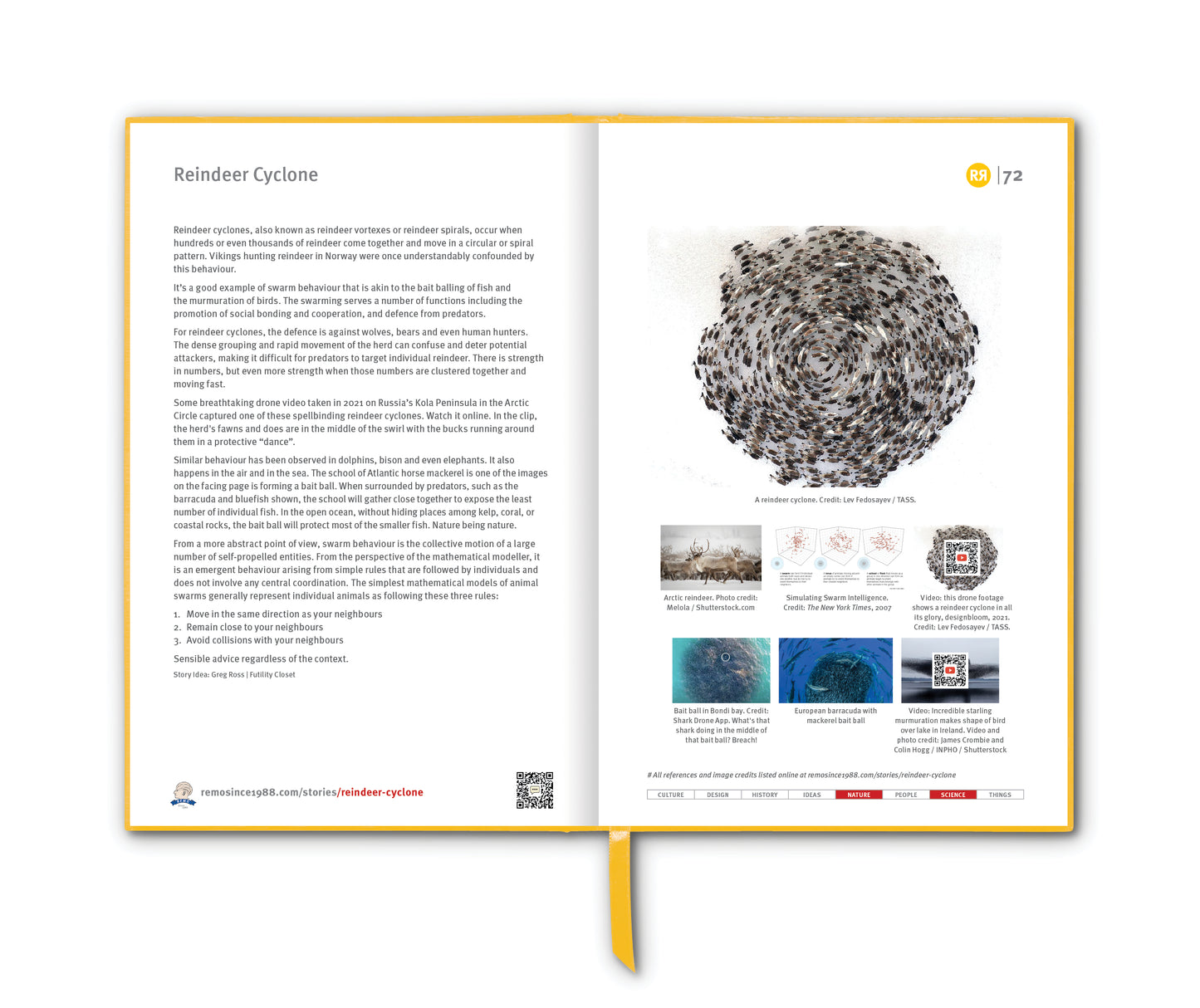

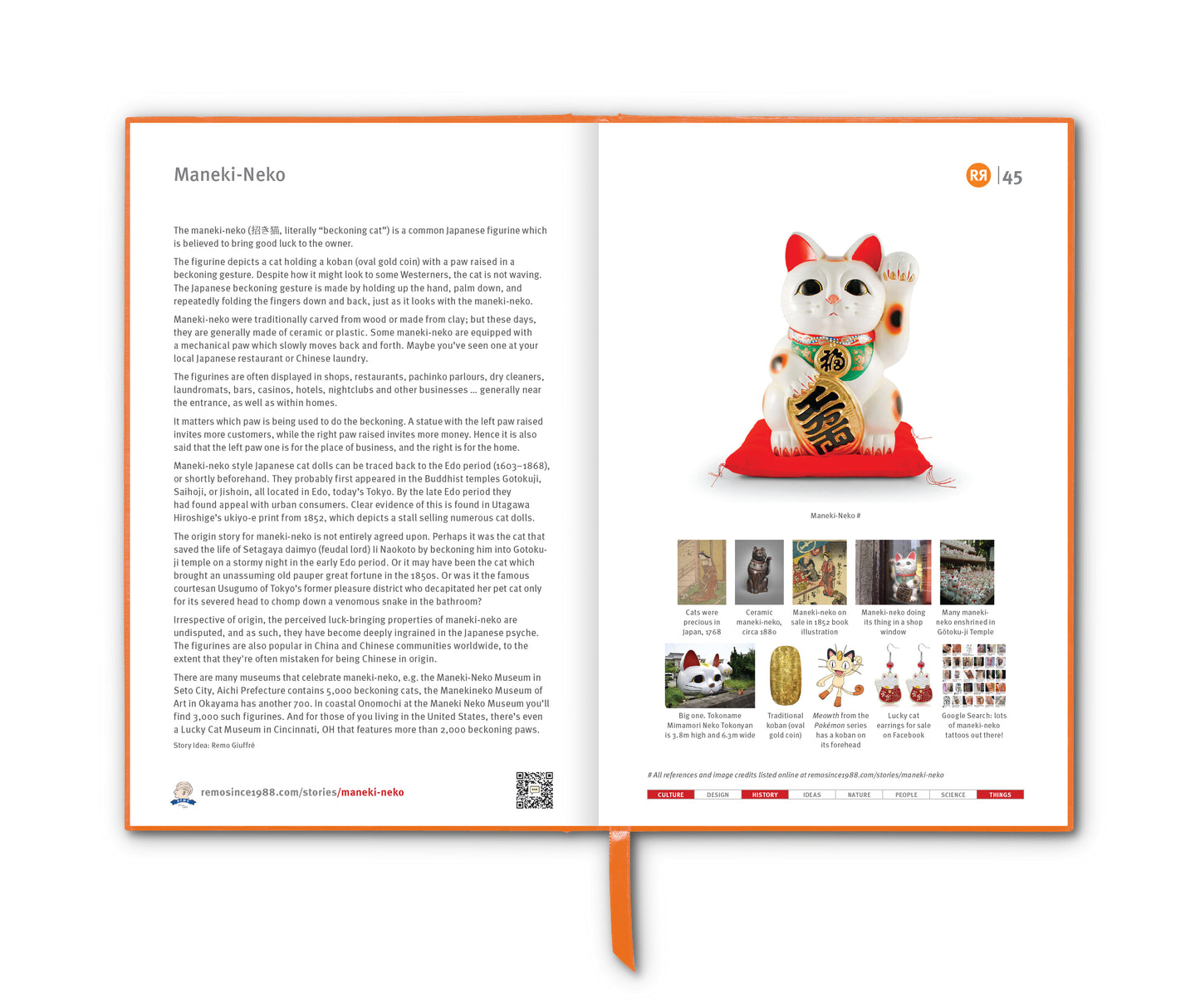

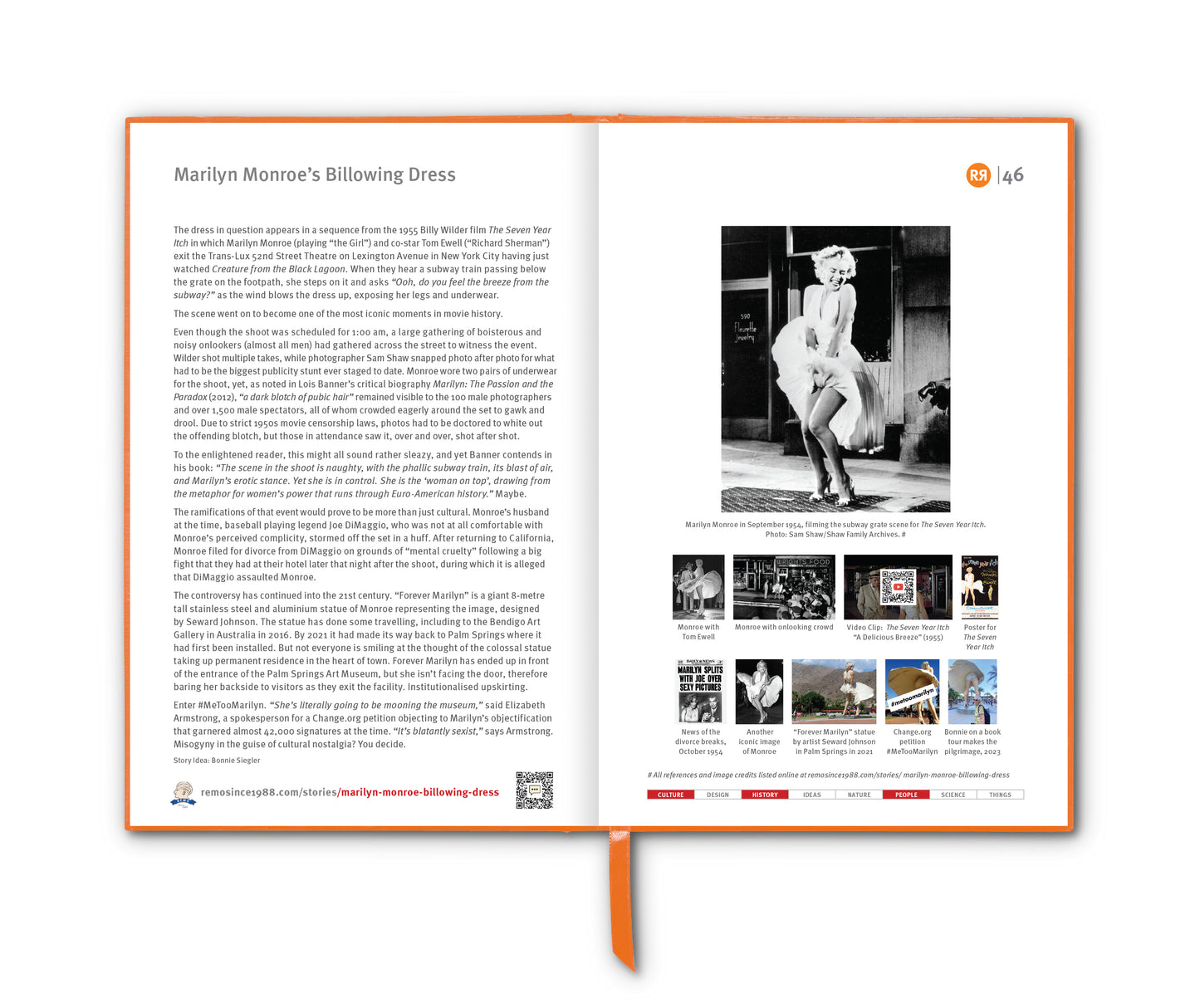

You’ve likely seen versions or depictions of this iconic chair on many occasions, and in a variety of places: homes, offices, restaurants, hotels; maybe even prisons and submarines. The chair features regularly in design magazines, TV series and movies e.g. The Matrix, The Dark Knight, Law & Order and CSI.

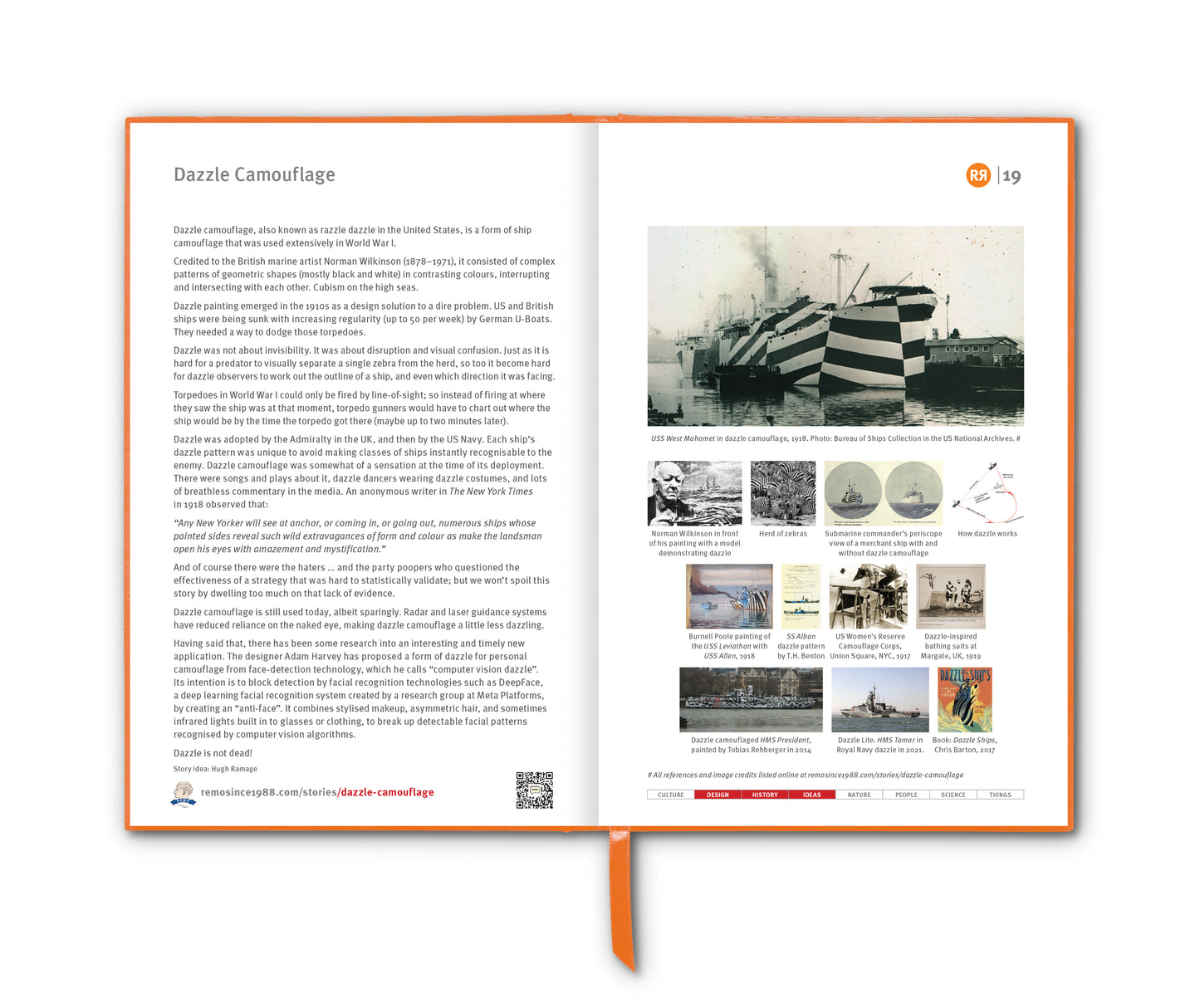

It’s called the 1006 (pronounced ten-oh-six) “Navy” chair, and it’s made in Hanover, Pennsylvania, by Emeco, a company that was created in 1944 just to make that specific chair.

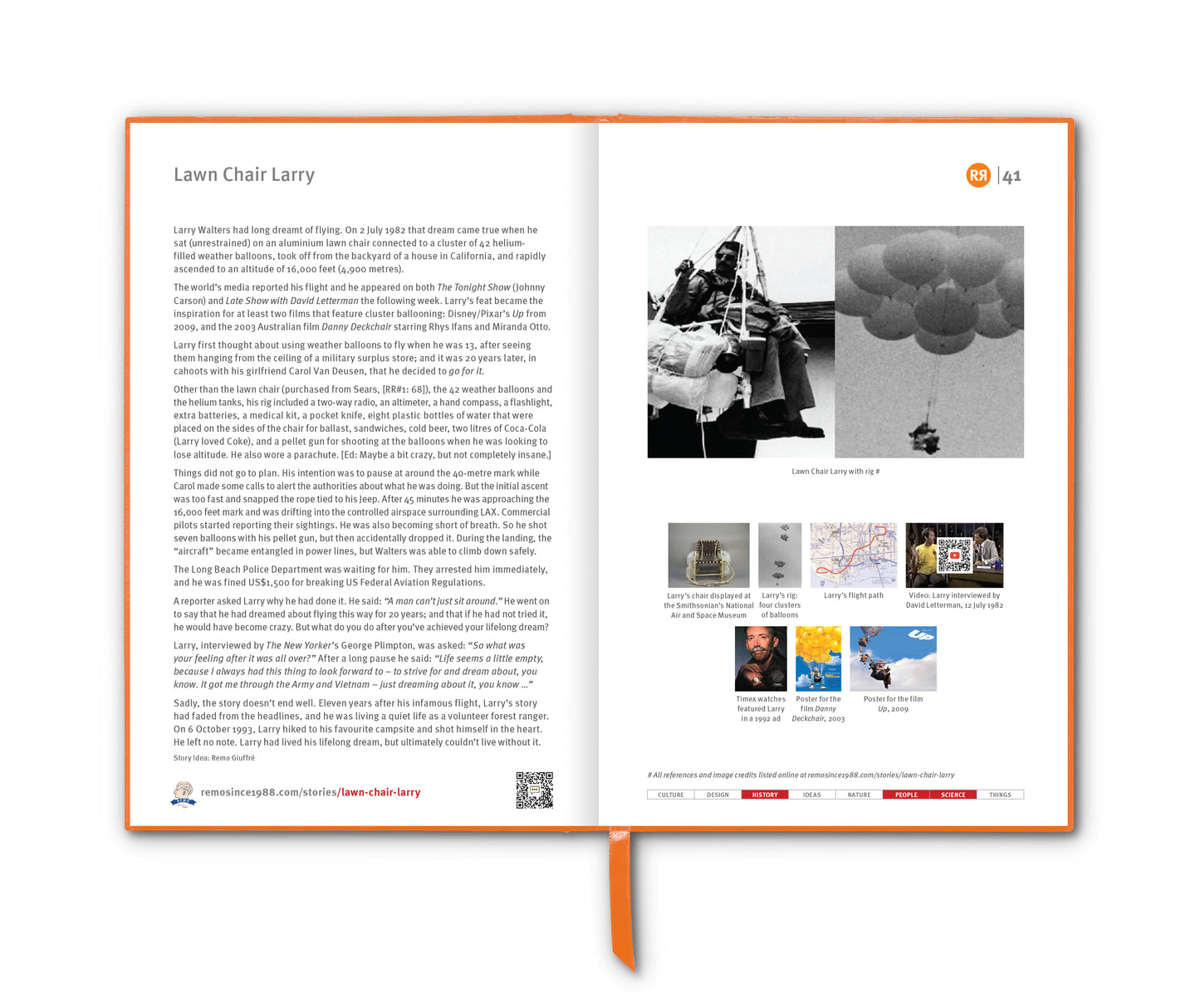

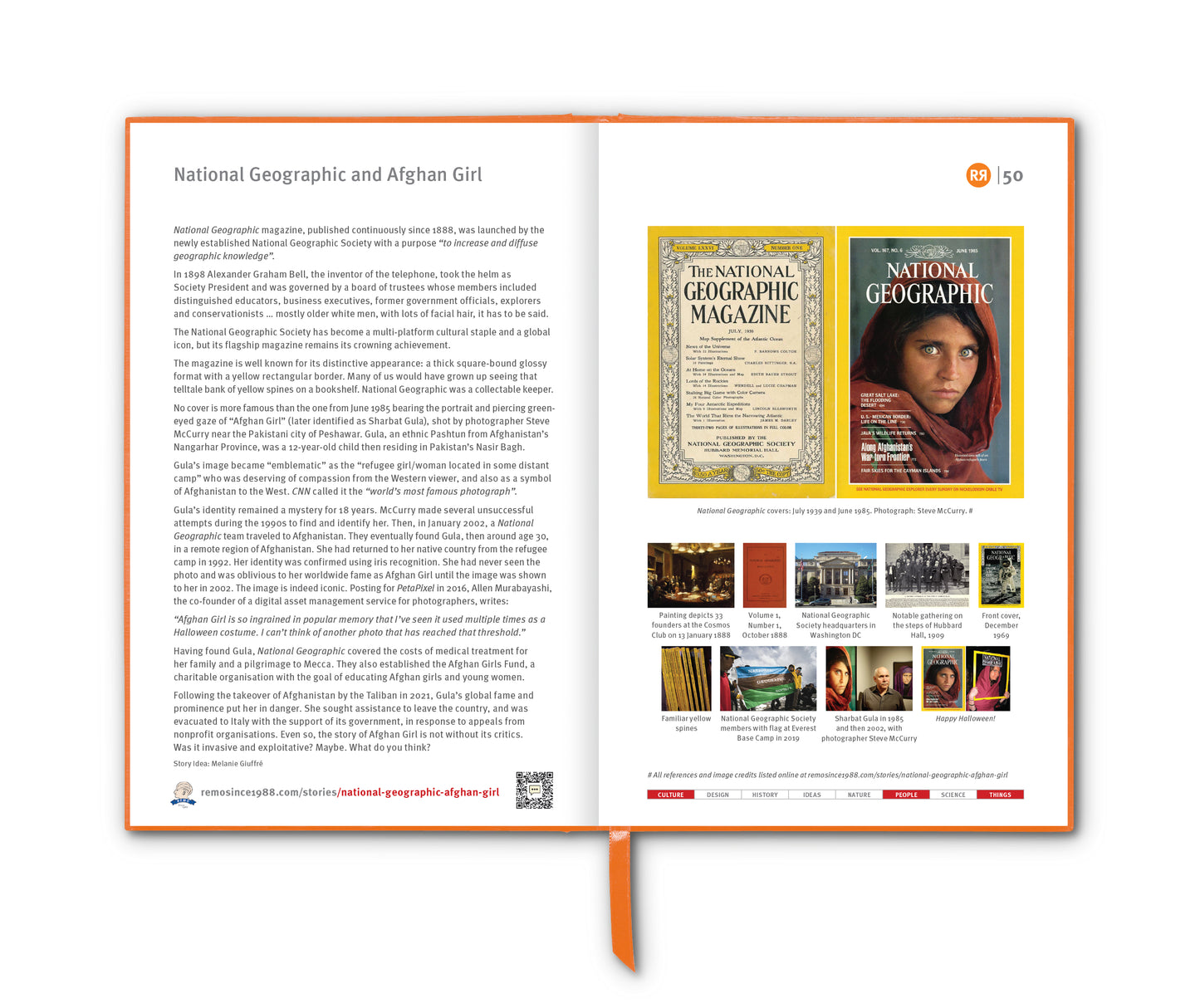

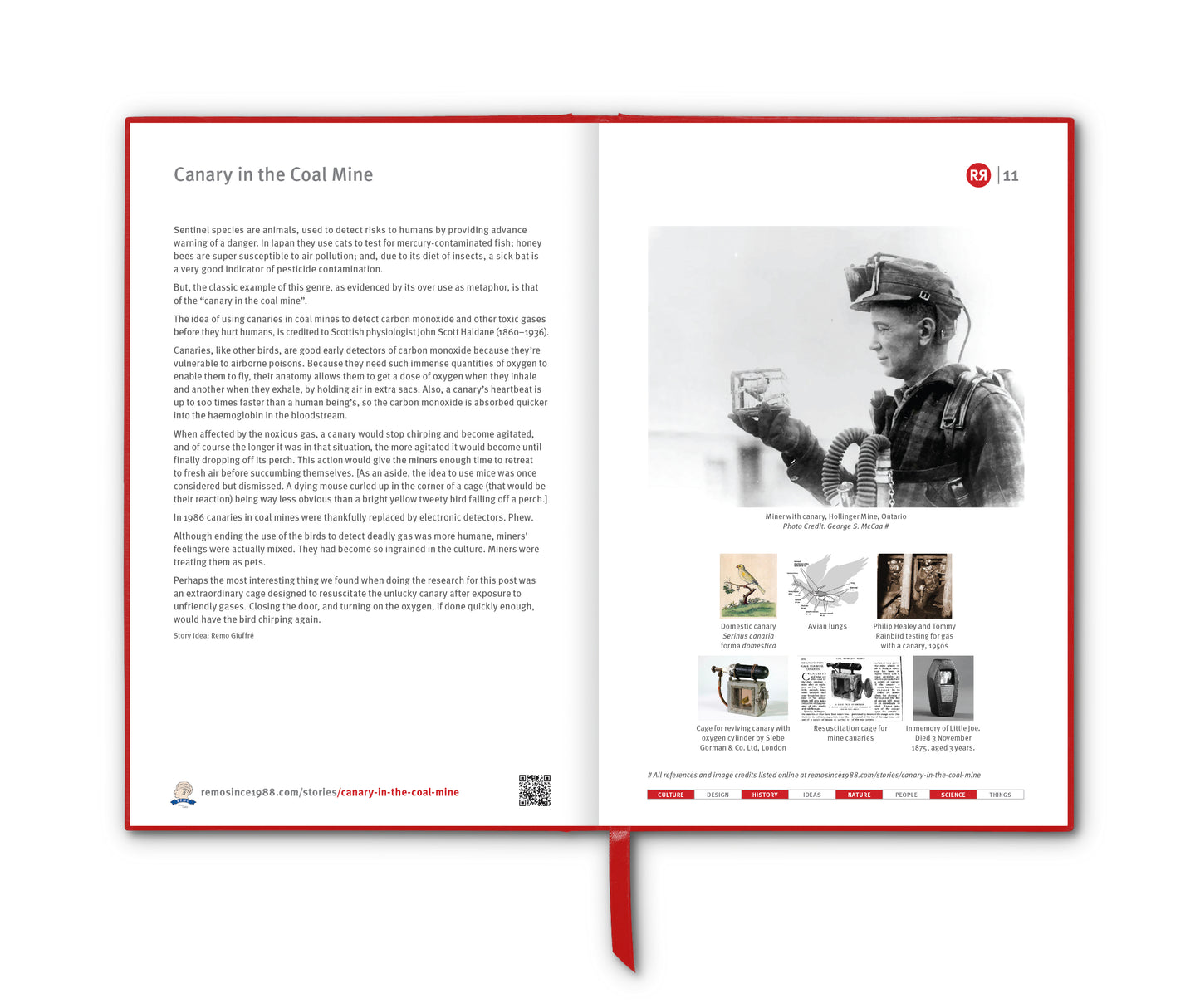

As the US war effort ramped up in the early 1940s, the Navy put out a request for design submissions. They needed a chair for the deck of battleships that was fireproof, waterproof and lightweight that could survive sea air and a torpedo blast to the side of the ship.

In response, an engineer named Wilton C. Dinges designed a chair made out of aluminium, bent and welded to be super strong. When competing for the Navy contract, Dinges is reported to have demonstrated the chair's remarkable durability by throwing it out of an eighth floor window of a Chicago hotel where the Navy was examining submissions. It bounced, but did not bend or break. The Navy gave its inventor the contract, and he, in turn, opened a factory and called his new business the Electrical Machine and Equipment Company, Emeco for short.

After the war, Emeco started selling 1006 chairs to prisons, hospitals and government offices. The chair was sold to restaurants in the 1980s and 1990s, then as a designer chair from the 2000s once the architects and interior designers cottoned on and started to order them for clients.

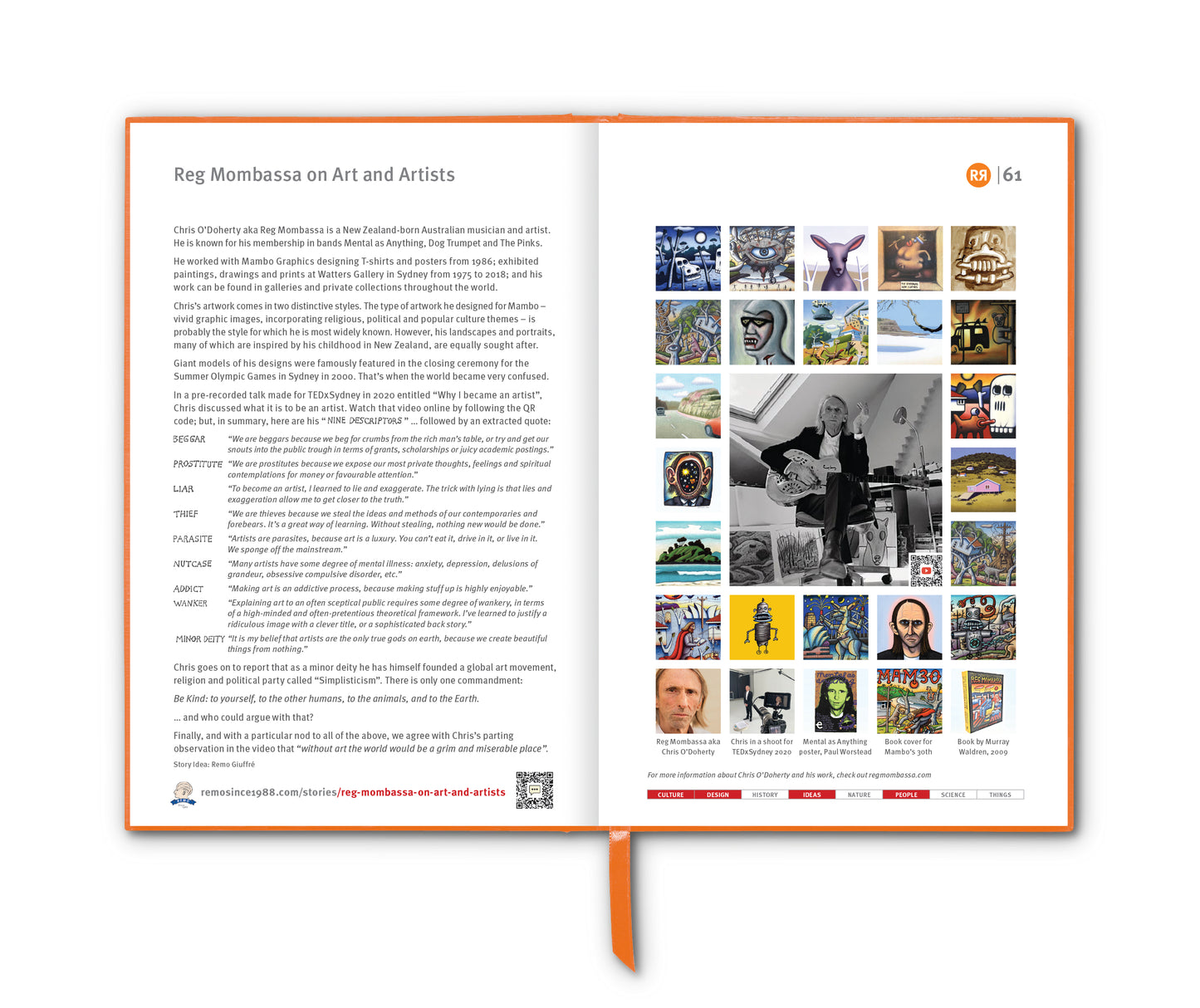

Today Emeco makes chairs in collaboration with architects and designers like Norman Foster, Frank Gehry and Philippe Starck. Their products are great, sustainability practice exceptional ... and their business is deservedly thriving.

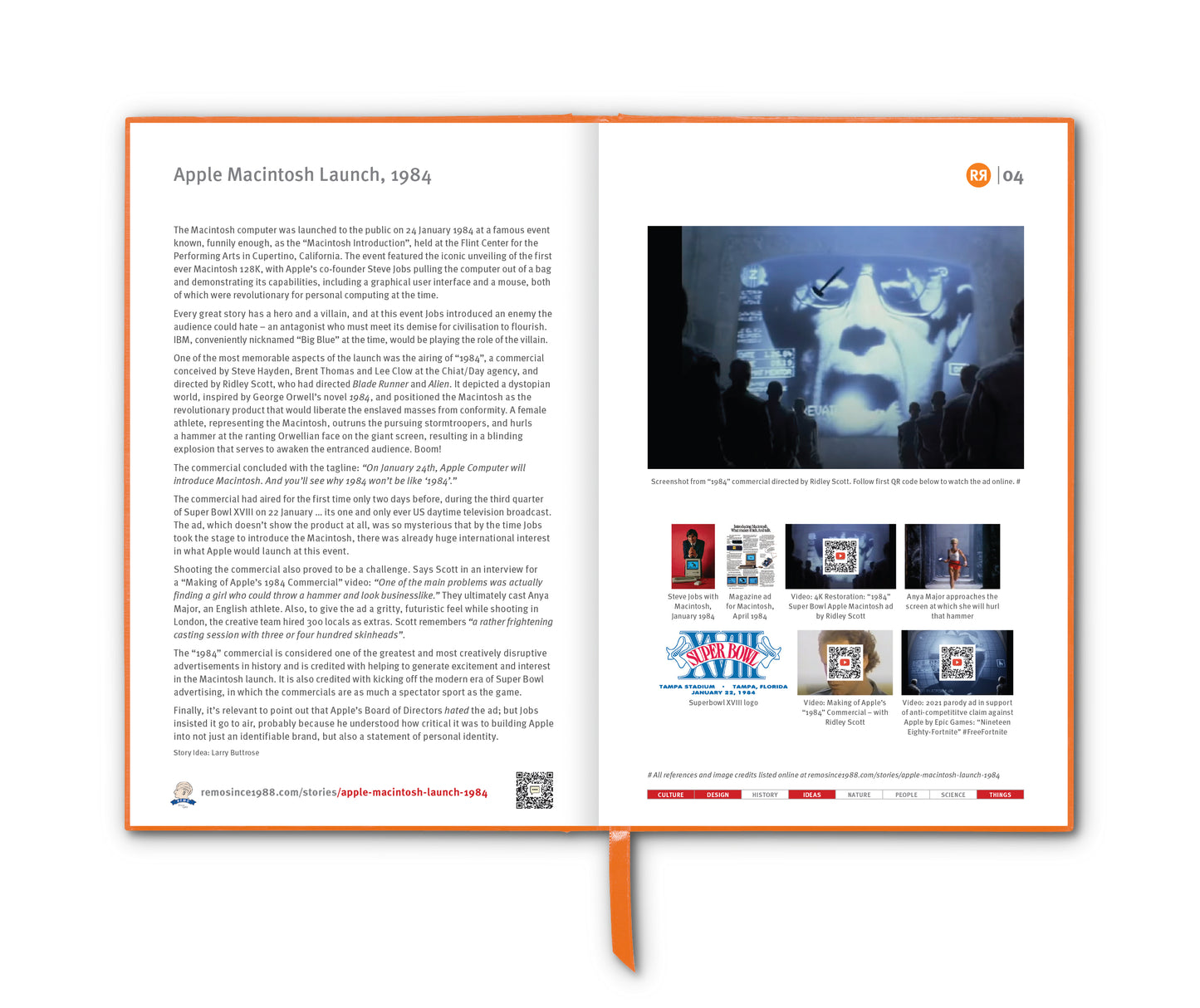

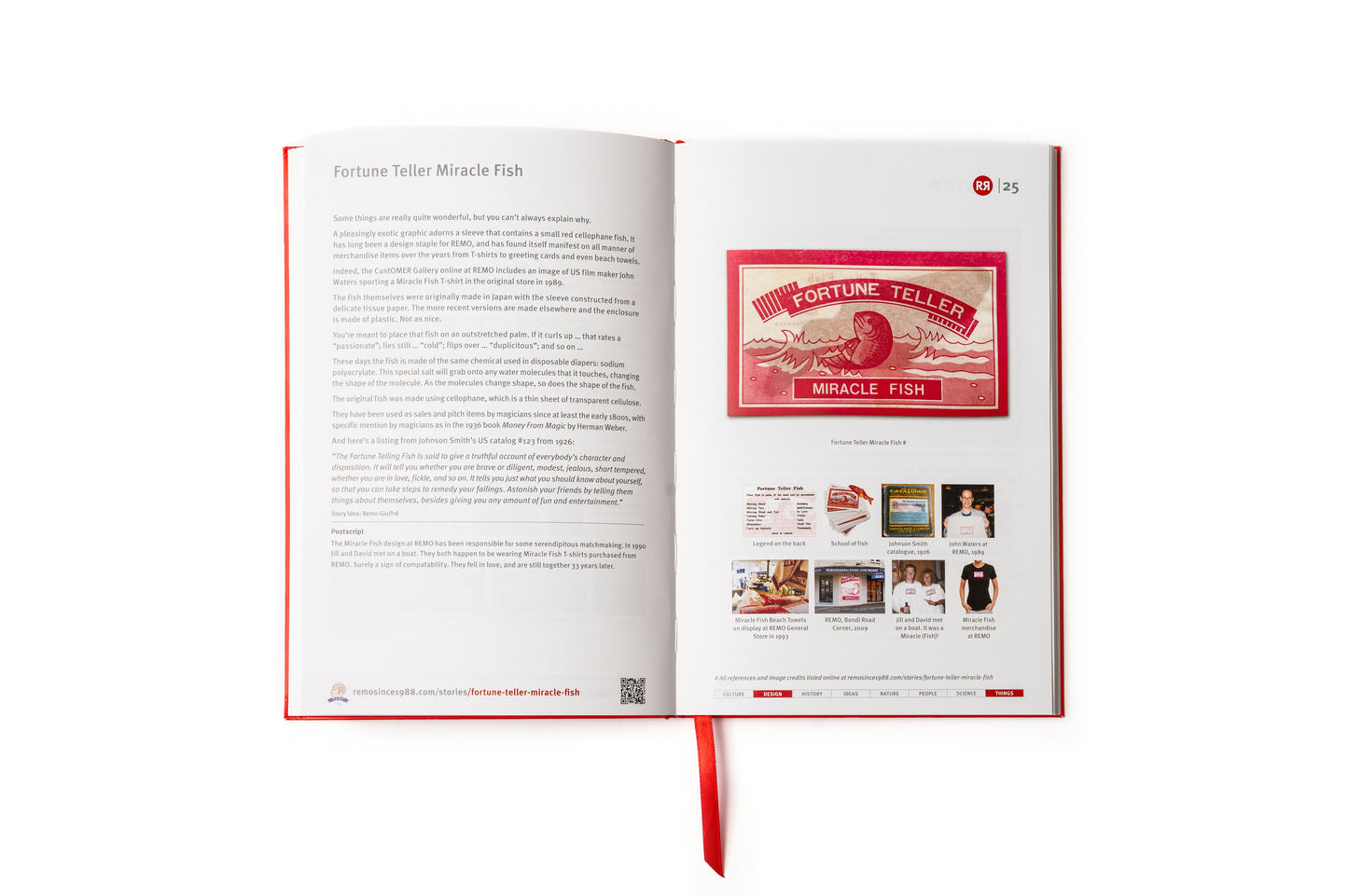

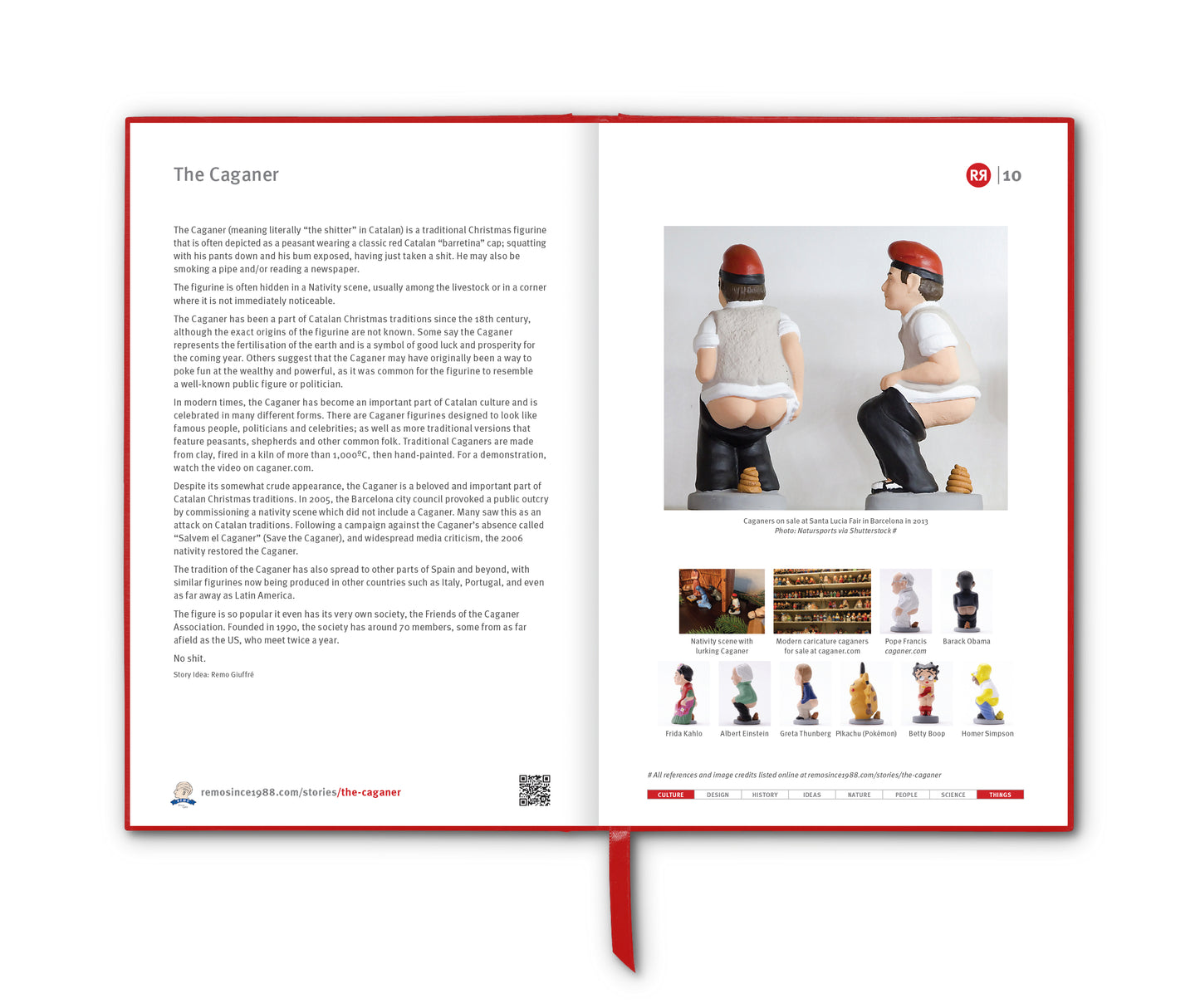

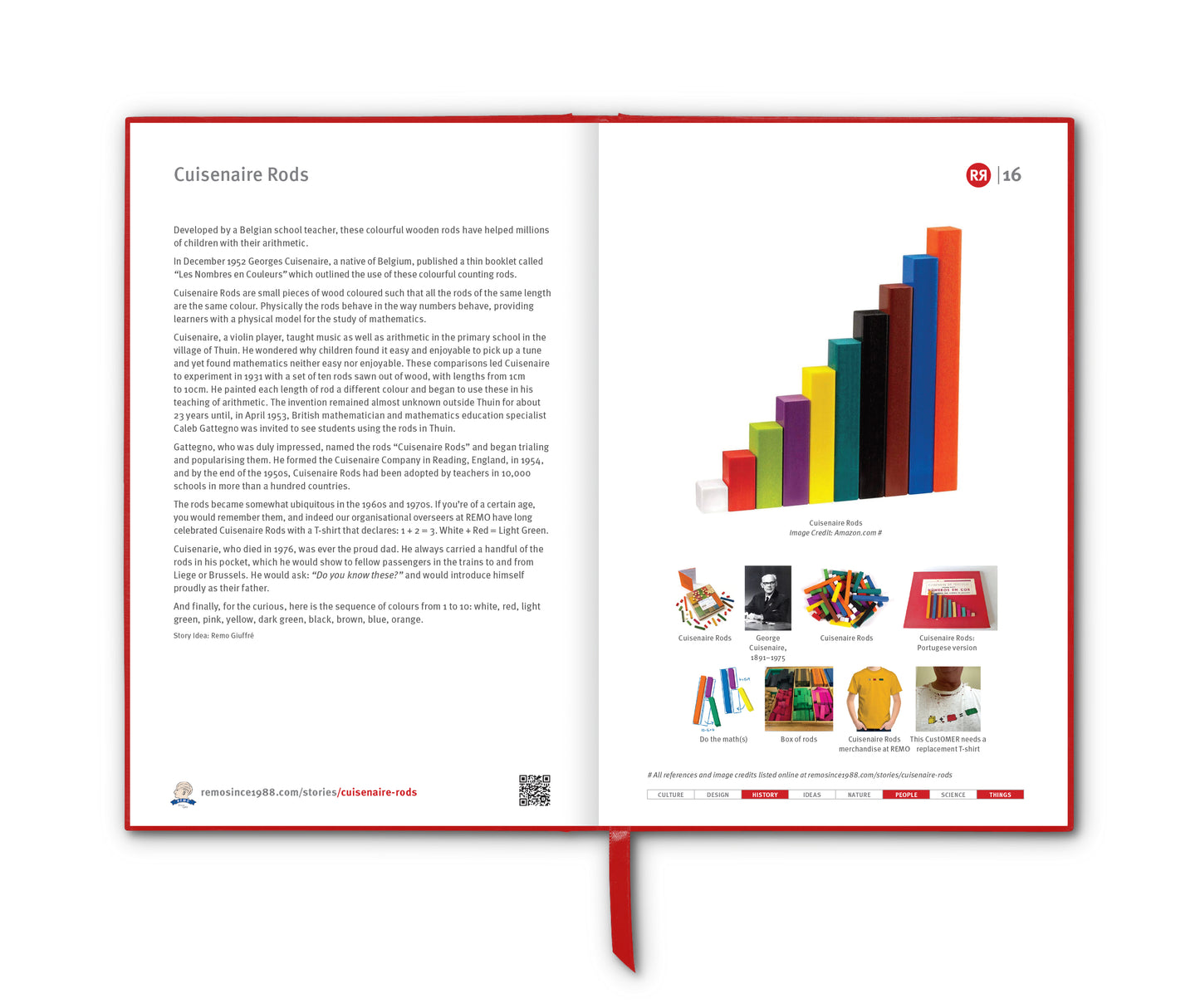

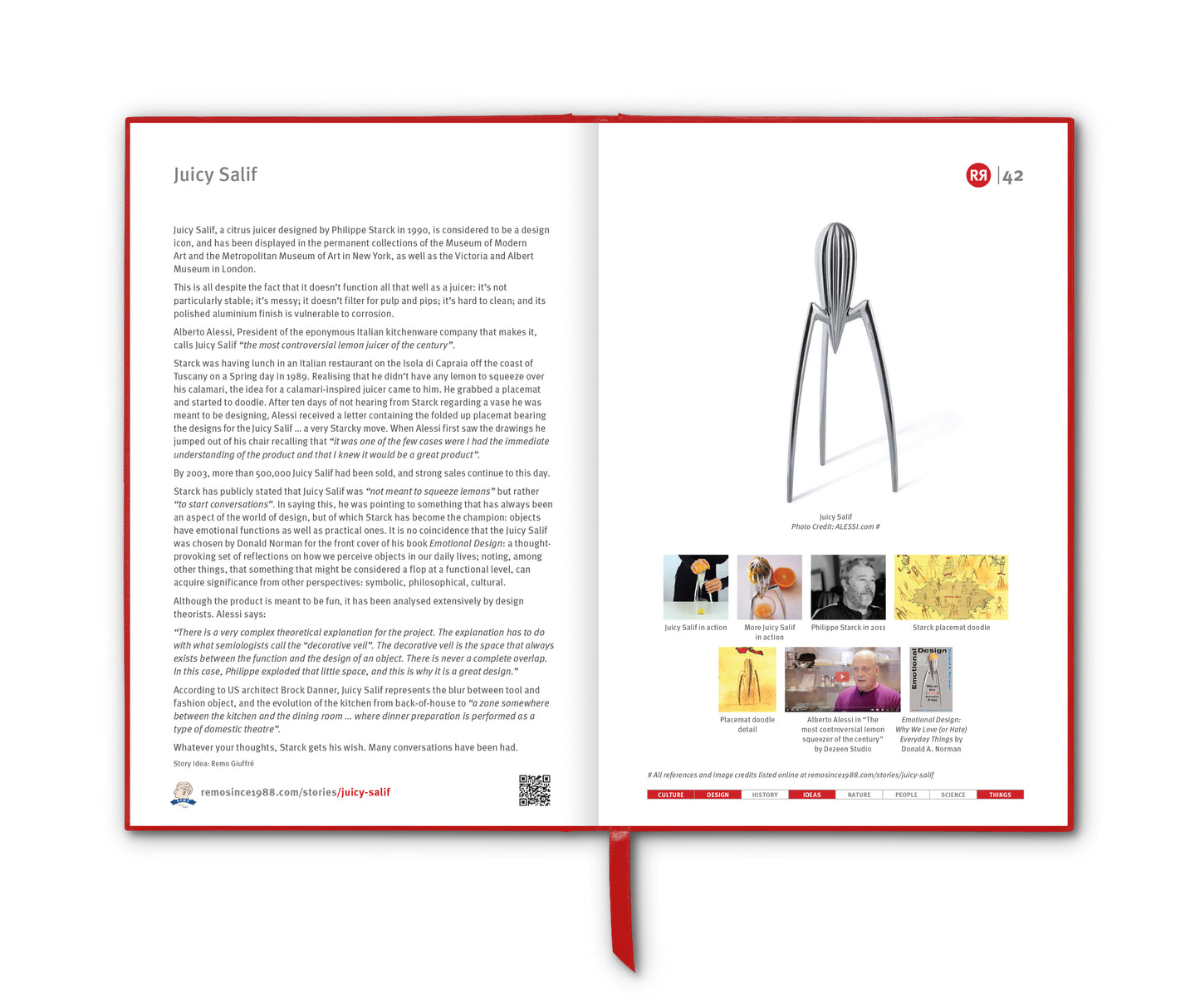

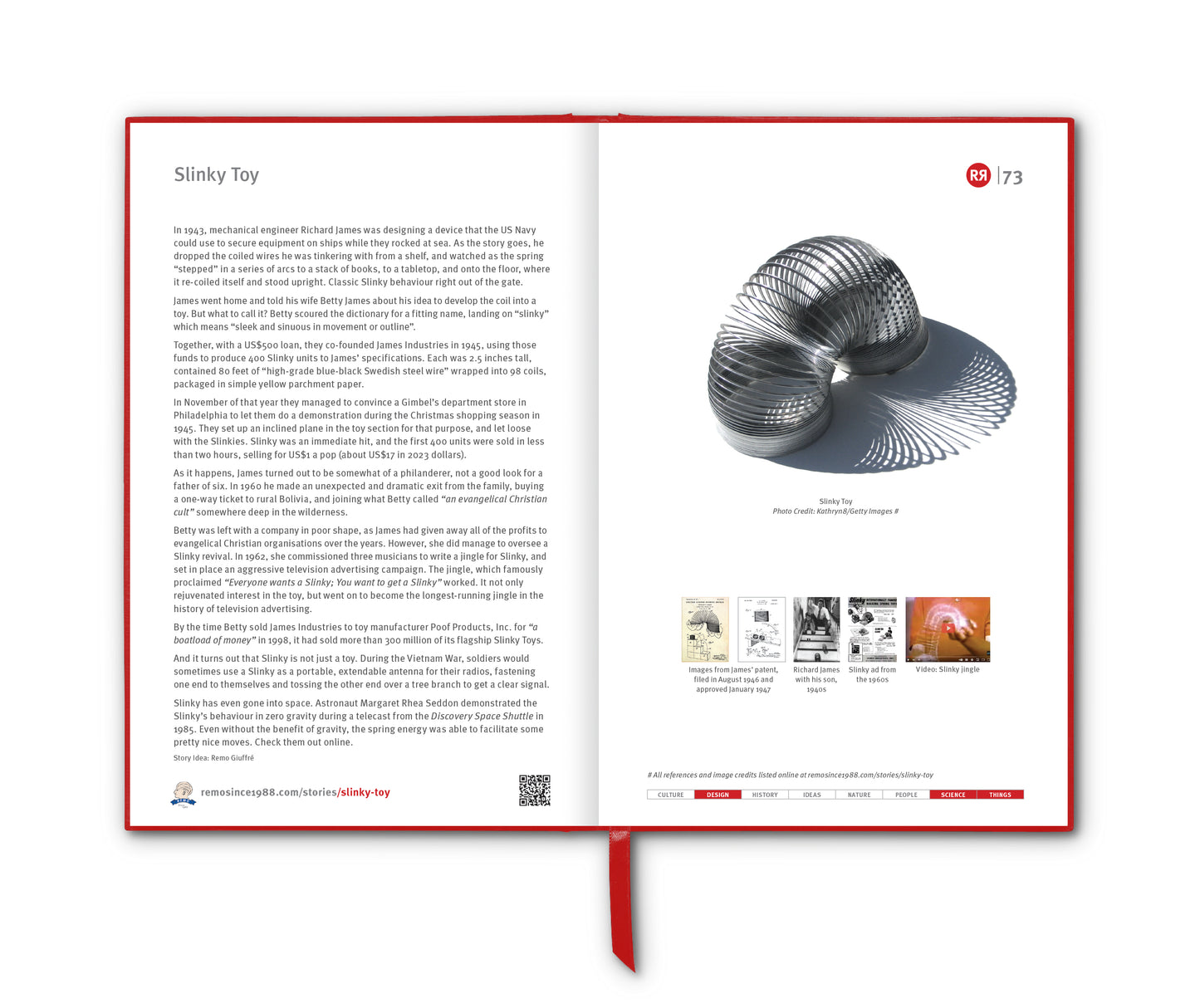

The original Emeco 1006 chair has a curved back with three vertical struts that stop at a crossbar short of the seat. There's a slight curve on the back legs. Sheets of aluminium are used to mould the distinctive seat bottom (which, according to legend, was modelled after the backside of Betty Grable, a famous Hollywood actress of the 1940s). The chair goes through a repeated heating and cooling cycle that increases the strength of the aluminium making it six times stronger than steel. It is guaranteed to last 150 years.

Beware of fakes and copies. There are many. In 2005, Target started selling an Emeco imitation supplied by Euro Style and, in October 2012, Emeco filed a lawsuit against US retailer Restoration Hardware for allegedly making unauthorised reproductions of the 1006. It was settled for an undisclosed sum. Emeco has also got Crate & Barrel and IKEA to take down fakes.

Emeco's chairs are still manufactured lovingly by hand in Hanover, Pennsylvania throughout a two-week, 77-step process. Indeed, in 2000 Eames Demetrios, the grandson of designer Charles Eames, published a documentary film on the manufacturing process called "77 Steps”. Watch it HERE, with more current footage of the process in an Emeco "We Make Chairs" film HERE.

Built to last.

____________________________

Emeco 1006 Navy Chair exists in printed form as chapter 21 of RR#1 … available to order HERE

____________________________

References

wikipedia.org/wiki/Emeco_1006

99percentinvisible.org/episode/77-steps/

emeco.net/about

Animated Video by Jean and Nicolas Jullien for Dezeen

Images

1. Emeco 1006 Navy Chair

2. US Navy Submarine

3. Original Design Drawings

4. Emeco Factory in Hanover, Pennsylvania

5. Sanding in the factory

6. Dipping for strength

7. Emeco at Home

8. Emeco in a Restaurant

9. Restoration Hardware Fake

10. Betty Grable

11. 1950s Advertisement for Emeco Chairs

12. Hand Made in the USA

2 comments

Ha. I have like 21 of them. 6 bar height. 6 starck counter. 5 regular. 4 counter. One of the best, mainly for build, weight, story.

I used to represent the M&Co. Design Group in New York, and I’m thinking that we may have scored some original Emeco chairs from a source they put us onto. Then we made contact with the factory in Pennsylvania to order a couple of extras. It was around 1997 and I don’t recall that they were that expensive. Even today, and knowing what I do about the labour intensity of their make, they seem inexpensive. Having lived with them already for decades makes me happy.